Ampoule Filling Machine For Cosmetics

Product Details:

- Type Pharmaceutical Packaging Machine

- Material SS

- Computerized No

- Control Mode Automatic

- Voltage 230V Volt (v)

- Weight (kg) 135 Kgs Kilograms (kg)

- Dimension (L*W*H) 900mm (L) X 750mm (W) X 1000mm (H) Millimeter (mm)

- Click to View more

Ampoule Filling Machine For Cosmetics Price And Quantity

- 1 Unit

- 150000.00 - 350000.00 INR/Piece

Ampoule Filling Machine For Cosmetics Product Specifications

- 230V Volt (v)

- No

- Pharmaceutical Packaging Machine

- Automatic

- Matt

- SS

- 900mm (L) X 750mm (W) X 1000mm (H) Millimeter (mm)

- 135 Kgs Kilograms (kg)

- 1 year

Ampoule Filling Machine For Cosmetics Trade Information

- Ahmedabad

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cheque

- 5 Unit Per Month

- 2 Week

- Contact us for information regarding our sample policy

- Wooden Packing

- Asia Australia North America Eastern Europe Middle East Western Europe Central America South America Africa

- All India

- ISO 9001

Product Description

Ampoule Filling Machine For Cosmetics

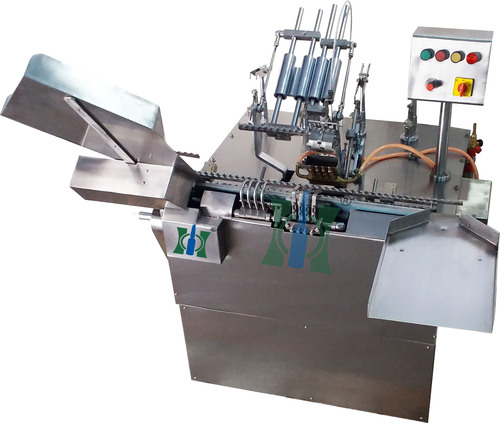

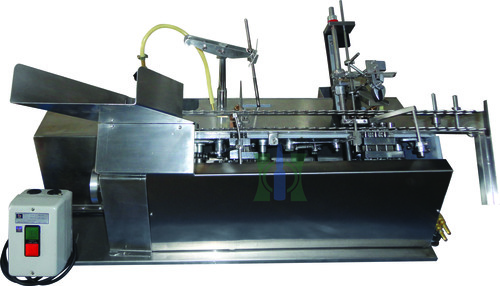

Harsiddh Two head ampoule filling and sealing machine is used to fill 0.5ml to 25ml liquid filling with 2 head fillers and sealers in a single dose applied to 1ml to 25ml open mouth glass ampoules. The production capacity of this machine is 30 to 40 ampoules per minute.

The slant travelling ampoule filling and sealing capacity varies based on the type, thickness and neck dimension of ampoules. The machine is made up of sturdy SS materials with minimum change over parts and easy maintenance. Single motor placement synchronized all the drives causes smooth rotation of ampoules at sealing station. Automatic sensors stop the filling as soon the machine doesn't found the ampoule.

Harsiddh Engineering is one of the leading firms known for delivering optimum performance pharmaceutical machineries. Ampoule Filler And Sealer are mechanized to load ampoules directly into the slant hopper. Ampoules move on eccentric rack following each other with the synchronization of star wheel. The machine carry on internal processes like pre and post gassing, filling, heating and sealing on stoppage of the rack. It is available in standard as well on customer specific requirement

- Compact structure free from vibration.

- Contact parts made from Stainless Steel AISI 316L.

- Non-contact parts made from Stainless Steel AISI 304, Mild Steel, Brass etc.

- Dosing Syringes/pumps and Filling Needles made of Stainless Steel AISI 316.

- All drives of the unit synchronized with Single motor.

- Pre & Post nitrogen flushing unit.

- Smooth ampoule rotating unit at the sealing station.

- Pre-Heating unit for thick glass ampoules.

- Easy regulation of oxygen, LPG and nitrogen gas with flow meters.

- No wastage of expensive liquids with No Ampoule No Filling feature.

- Easy regulation of speed with variable frequency drive.

- Vertical tray collection unit duly filled and sealed ampoules (Optional).

- Stainless Steel west tips collector at the bottom side of machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ampoule Filling Machine' category

|

HARSIDDH ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry