Call : 08045475338

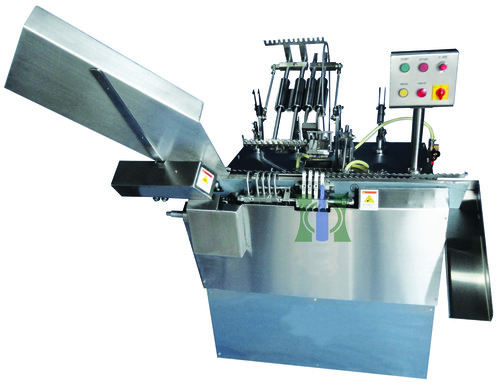

Servo Based Ampoule Filling Machine

50000.00 - 150000.00 INR/Piece

Product Details:

- Type Pharmaceutical Packaging Machine

- Material SS

- Capacity 1ml to 25ml Milliliter (ML)

- Computerized No

- Control Mode Automatic

- Voltage 415V Volt (v)

- Power 0.5HP Horsepower (HP)

- Click to View more

X

Servo Based Ampoule Filling Machine Price And Quantity

- 50000.00 - 150000.00 INR/Piece

- 1 Unit

Servo Based Ampoule Filling Machine Product Specifications

- 415V Volt (v)

- 1ml to 25ml Milliliter (ML)

- 0.5HP Horsepower (HP)

- Pharmaceutical Packaging Machine

- Automatic

- SS

- 750mm (L) X 500mm (W) X 1000mm (H) Millimeter (mm)

- Matt

- 1 Year

- No

- 70 Kgs Kilograms (kg)

Servo Based Ampoule Filling Machine Trade Information

- Ahmedabad

- Telegraphic Transfer (T/T) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cheque

- 10 Unit Per Month

- 2 Week

- Contact us for information regarding our sample policy

- Export Worthy Wooden Packing

- Australia South America Middle East Western Europe Asia Central America Eastern Europe North America Africa

- All India

- ISO 9001 CE

Product Description

Servo Based Ampoule Filling Machine

Our single head ampoule filling and sealing machine is mostly used in pharmaceutical injection preparation For fill and close sterile glass ampoules.

Technical Specification :

- Model : HFS-30 (Slant Travel) Off-Line model

- No. Of Head : One

- Ampoule Size : 1ml to 25ml (Dia. 10mm to 22mm)

- Production / Minute : 10 to 15

- Filling Accuracy : ± 1%

- Filling Type : Piston Pumps Type Filling (Volumetric)

- Required Gas For Sealing : LPG + Oxygen

- Pre Heating : Available

- Nitrogen Flushing : Available (Pre & Post)

- Contact Parts : Stainless Steel S 316

- Non-Contact Parts : Stainless Steel 304 / M.S. Powder Coated / Nickel Plated

- Power Required : 0.5 H.P., 380-415V, 3Phase, 4 Wire Systems

- Dimension : 910mm (L) X 650mm (W) X 950mm (H)

- Net Weight ; 70

- Gross Weight : 180 Approx

Salient Features :

- cGMP model

- Compact and vibration free structure

- All Contact parts made from Stainless Steel AISI 316 material

- Other parts (non-contact) made from Stainless Steel AISI 304, Mild Steel, Brass etc

- Stainless Steel AISI 316 Dosing Syringes and Filling Needles

- Single motor synchronized all drives of the unit

- Smooth ampoule rotating unit at the sealing station

- Pre & Post nitrogen flushing unit

- Pre Heating unit available for thick glass ampoules

- Flow meters for Nitrogen, LPG and Oxygen gas regulation easier

- No Ampoule No Filling function avoid consumption of expensive liquids

- Minimum time to change over ampoule size

- Variable frequency drive for regulating machine speed easier through speed pot

- Vertical tray collection unit duly filled and sealed ampoules

- Stainless Steel west tips collector for cutting the glass ampoules tips while sealing

- Suitable for all open mouth glass ampoules

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ampoule Filling & Sealing Machine' category

|

HARSIDDH ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry